Quality Assurance

Quality is Important to Us

Infinity Fasteners adheres to a "whatever it takes" attitude to provide exceptional quality products and services to our customers. "Exceptional quality" includes providing the correct product, on time, every time, and the services that help our customers achieve their goals. Infinity Fasteners also follows a Shared Values Philosophy that frames our "whatever it takes" attitude.

Infinity Fasteners adheres to a "whatever it takes" attitude to provide exceptional quality products and services to our customers. "Exceptional quality" includes providing the correct product, on time, every time, and the services that help our customers achieve their goals. Infinity Fasteners also follows a Shared Values Philosophy that frames our "whatever it takes" attitude.

Infinity Fasteners completed the ISO 9001:2015 audit and is proud to be ISO certified. We are dedicated to maintain and certify our high standards of excellence, delivering accurate and quality service with every order.

Infinity Fasteners, a Keller & Kalmbach Company, places highest value on the quality of its products, processes and services. Our quality philosophy is evident in everyday business. Since 1980, a certified management system has been an integral part of Keller & Kalmbach´s business. Modern quality methods, such as Kaizen, Ishikawa/risk analyses and FMEA are used for support. An extensive selection of test equipment is available for product verification. More than 25 employees are active in quality management, in order to monitor supplier evaluation and auditing, as well as products and processes. Application engineering, consultation and product range optimization are carried out, incorporating a very high level of quality. As a reliable partner, Keller & Kalmbach has already been a supplier for many years to volume production in the automobile industry.

- 1/A-supplier to the German Railways and the VW Group as well as Siemens, Krones, AGCO Fendt etc.

- Comprehensive testing equipment

- Customized quality testing

- Application of KAIZEN (e.g. 5S method)

- Centre of Distribution at Hilpoltstein with integrated quality assurance

-

Certified in accordance with:

- DIN ISO 9001:2008

- VDA 6.2 (German Automakers Association)

- Technical application consulting

- Customized quality testing

- Optimization of existing applications

- Member of DIN (Deutsches Institut für Normung e. V.)

- Cooperation with renowned external institutes, e.g. for extended investigations

- Extensive product knowledge

- Contact person for quality-related topics

- Continuous improvement

- Strategies for process optimization

- Hardness, tensile, measurement, grinding cut testing

- Eddy current tests

- Scanning microscopy testing (external)

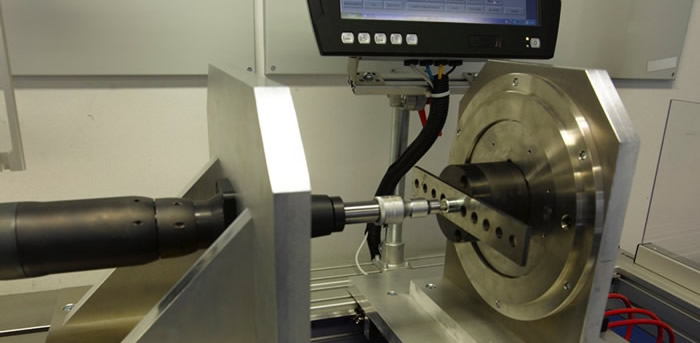

- Friction coefficient testing

- Threading coefficients (screwing in, torsion and other torques)

- Testing the surface coating in the corrosion test chamber (according to VDA standard)

- Generation of First Sample Test Reports according to PPF or PPAP Standard

Measuring Instruments

Extensive equipment for the highest standards of quality

- Friction coefficient investigation

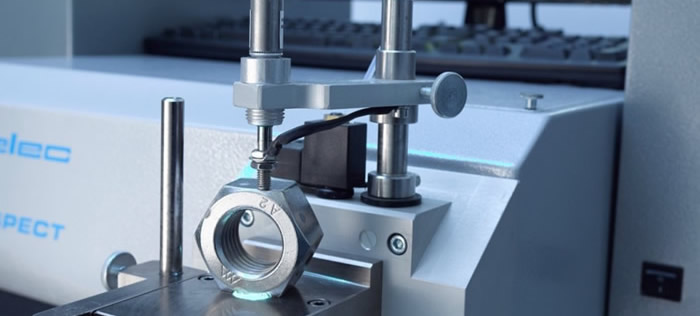

- Eddy current testing instrument

- X-ray fluorescence

- Roughness testing device

- Tensile testing machine 60 t

- Hardness testing with video evaluation

- Concentricity testing instrument

- Profile projector

- Coating thickness, material analysis testing instrument

- Form measuring instrument

- Torque measurement head with measurement sensors

- Torque wrench

- Measurement amplifier

- Measuring rings

- Contourograph

- Measurement plate

- Headstock

- Grinding specimen preparation

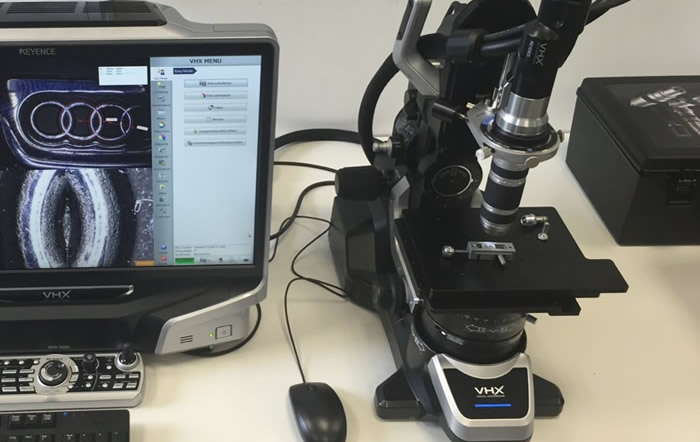

- Microscope

- Spectral analysis unit

- Various other measurement aids

- Application: varied coating thickness checking

- X-ray fluorescence procedure

- Only able to be tested on steel

- Testing conforms to ROHS

- Interference-free coating thickness measurement of corrosion protection coatings

- Simple determination of surface composition

- Application: Hardness testing

- Core hardness

- Only able to be tested on steelSurface hardness (sheet metal screw, self-tapping screw)

- Testing according to the Vickers procedure

- Application: tightening torque

- Tightening angle

- Loosening torque

- Friction determination for head-thread total friction

- Pretension force

- Testing in accordance with the standard and German Automakers Association

- Application: Corrosion tests and evaluations

- In accordance with DIN EN ISO 9227

- German Automakers Association standard

- Typical testing times are 96h, 240h, 480h or 720h

- Standardized cross-validation for analyzing protective coatings

- Application: Screws and nuts from M5 – M27

- Destructive test

- Clamping and straining the part until breakage

- Assessing the tensile strength

- Determination of alloy composition

- Identification of steel grades

- Determines all dimensions of the visible outline with incident light as well as transmitted light

- After programming in a part, up to 99 other parts are automatically and simultaneously measurable

- Faulty parts and their dimensions immediately displayed

- Measuring program for external thread (core diameter, pitch diameter, thread angle)

- Magnification 20 – 1000x

- Depth of field

- 3D display

- Surface analysis / measurement